Select The Right ERP For Your Manufacturing Needs

Finding the right manufacturing ERP software for your organisation is a challenge, but it’s well worth it for a huge number of benefits it can bring. Understanding how a manufacturing ERP is designed to streamline and optimise your day-to-day needs as a manufacturing business will help you find the right vendor.

Understanding ERP in Manufacturing

- Inventory management - Ensure you’re always operating with optimal inventory levels to keep production going, even spread across multiple locations.

- Automated processes – Save your employees plenty of time, helping them focus on delivering great results.

- Quality control - Utilise inbuilt tools to ensure you can keep track of product quality, ensuring things are delivered consistently and on time.

The Power of ERP in Manufacturing

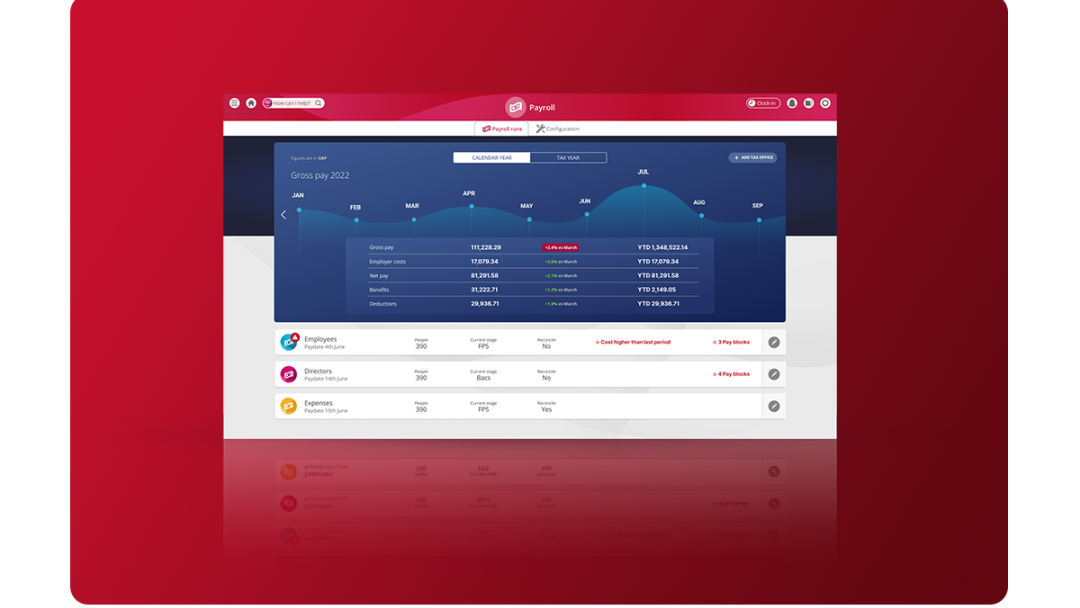

We Pay 2.5 Million People

Challenges and Solutions in ERP Manufacturing

Book your Manufacturing ERP Demo Today

Implementing ERP Manufacturing Effectively

Implementing manufacturing ERP software can be pretty complex, so it’s important to have a plan going in. This will make the process as smooth as possible.

Planning

Assessing your current capabilities and needs is a vital part of any ERP implementation process, as it will help you find a solution that suits you perfectly, both for the present and the future.

Preparation

You’ll also need to clean up your data to prepare it for migration, as well as creating backups in case something goes wrong. Make sure to conduct thorough audits. You may also need to train up your employees on the new system.

Data Migration

Once your data has been migrated, you’ll need to test, test and test again to make sure everything’s gone as expected. Validate your data, test your workflows and confirm everything’s compatible.

Cost of Ownership

With good training and adequate prep, you’ll massively speed up your return on investment, and reduce the cost of ownership. Establish an ongoing maintenance program and be ready to handle any troubleshooting queries.

The Future of ERP in Manufacturing

There are many future trends that ERP solutions will need to account for. One of the most critical is immediate access through mobile apps, which makes it easier to respond to changes in real-time. Cloud-based ERPs are also important, as this enables real-time data to be used more effectively. Machine learning is also becoming more important as it enables stronger predictive analytics.